Doing it right, really isn’t that easy.

Especially if you don’t have experience. Importing correctly almost takes a sixth sense.

There’s the Amazon style guru or the trade company that wants buyers to know how “easy” everything is.

“Simply find something on Alibaba, place your order and everything will be underway.”

This article inspired my post

How to Lose Thousands of Dollars on Amazon

It’s not always another company that sells overseas manufacturing and importing as the easiest thing in the world.

Sometimes our own mind tells us what we want to hear.

The new product developer starting out their brand.

The corporate buyer who must fulfill timelines and inventory.

They’re zealous to get product to market.

They’re tempted to skip steps, because, you know, the factory produces this everyday. How hard can it be?

The drive for passive income helps fuel the narrative. It’s that magic step everyone wants to take from worker harder to now working smarter.

China and offshore importing are presented too much as “have it your way”.

The overlooked concepts of importing

Importing requires a time investment

Many of these gurus teach their clients that the effort you spend is on branding, keywords or learning an algorithm.

[from the Atlantic article]

Amazon stores have good sales, so they could then pick a product in one of those stores that can be retailed for five to 10 times what it costs to produce it in China.

I’m not trying to take anything out of context and I urge you to read the entire article.

The idea though is that you “simply pick a product.”

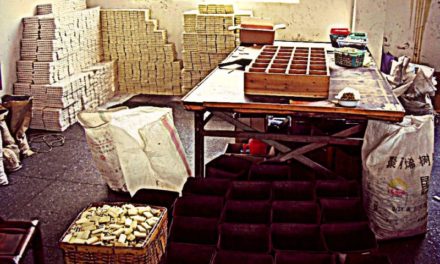

It leaves out the hours of communicating with and vetting suppliers.

There’s timing in making samples, not to mention the cost and wasted time once samples are wrong.

There’s time from when deposits change hands to when the actual order finishes.

[from the Atlantic article]

Customers pay for three months of webinars and coaching, but, he told me, it takes much longer for products to actually arrive in Amazon’s warehouses from China and start selling.

Loss of money in getting it wrong.

[from the Atlantic article]

And then there are the everyday issues that come with shipping and selling internationally: People at the seminar told me the products they’d ordered from China were defective, and customers started leaving bad reviews.

These are not everyday issues.

Defective products are issues that are avoidable and controllable when buyers understand importing. I’ve been apart of a multitude of China orders and the overwhelmingly large portion DID NOT have an “everyday issue” of defective quality.

When there’s defective quality, it’s to be rejected.

Better yet, good control over a factory and an order, help to eliminate the surprise of substandard quality.

It doesn’t have to be a gamble where you don’t know the quality until you send in a team or until the product arrives…see next point.

No concept of on-going order control

The garden variety guru presents the idea that you “simply place your order and then wait”.

It includes the assumption that the overseas factory has good order control.

They peddle a false assurance that ordering from a factory is the same as ordering from Amazon (I hate it when you see Alibaba referred to as a “wholesale site”. That’s ignorance).

Again, to lean back on my years of experience, the successful orders were almost never hands off.

- There was daily contact with the factory.

- There’s management on current phase of production.

- If there are 3rd party components, and the main factory is casual, knowledgeable buyers sometimes have to act as another set of eyes and ears.

How about timing?

Orders don’t just deliver on time because a buyer enjoys their wait.

There is the strong sense that the squeaky wheel gets the most attention when it comes to managing a vendor.

Long-term quality focus:

“We did check the goods but long-term usage of the product wasn’t considered.”

If you’re an expert in your brand, you have to also be an expert in the quality and functionality of your product.

Granted you may be a 1-man or 2-man show, but you’ll still need to understand your own product.

You cannot outsource your product understanding.

Overtime you’ll scale and hire people who understand items.

Lack of transparency in quickie orders in and out…

Not only quality, but there are regulations and standards to consider.

I’ve heard buyers say “my order arrived ok, but customs is asking for a certain testing”

Or, “now the retailer is asking for a certain document…”

And when you went in, not knowing the battle ahead of you, you haven’t the slightest clue what any of this could mean.

Relying on manufacturing errors to teach you about your own product is very costly.

The manufacturing leg of bringing a product to market, shouldn’t be considered an afterthought.

China Sourcing Basics

Let me share what I've learned about China Sourcing.

Provide your email & receive free ebook: 40 Tips for Emailing China Suppliers.

I'll never spam. I'll share tips on Private Labeling, Sourcing and China Business.

You have Successfully Subscribed!