Many times in China sourcing, during the sampling and pre-order steps, the quoted price goes up. Is it supplier blunder, something diabolical or reasonable ebb-and-flow of pricing that client should expect in early stages?

Evolving detail from client side makes difference on quoted price

This should really go without saying. A change in spec likely assumes a change in the quoted price.

Keep in mind, for many industries, when suppliers quote, there’s not a ton of room to absorb little changes here and there.

Buyers tend to have a casualness when adding new specs to the mix. They flippantly say “let’s increase that by 5cm” not realizing that when there’s a large quantity that a 5cm increase, for example, has great bearing on pricing. Not to mention the change increases the size of the item, thus increasing the shipping. If you’re talking 100,000 piece order, 5cm increase on each item can be the difference of 4 containers versus 6 containers.

Some changes may seem to be equivalent; in other words, what seemed to be the same as the existing actually requires a different process. Suppliers, because of lack of communication, don’t explain these things clearly.

From the buyers’ perspective, it seems the supplier isn’t careful in pricing.

Presented concept, to quoted concept

You may send a concept to a supplier. By concept I mean mock-up, drawings, visuals and description. This especially applies to developing a product. You send a concept, they quoted you on a concept.

Hi concept. Meet my friend concept’s price.

When a supplier quotes your concept, consider this fluid. Many buyers, especially in the fast-paced industries and quickie quoting requirement worlds, have a convenient assumption that the supplier is a highly precise humanoid robot that is able to quote concepts with exact precision.

I jest but not really. Just remember that if you’re dealing in development and concepts, until hand is put to plow and sampling starts, the price is subject to change.

Lack of heavy scrutinization prior to certain steps

This is the one that seems diabolical but it’s actually for various reasons. For many industries and many suppliers that have a very high volume of quotes, they simply do not pay much attention to the initial RFQ process.

For example you hear this a lot, “they quote you low to get you in”. It’s more like they quoted you low because they didn’t fully analyze the project and if you want a firmer quote then you “have to get in”.

It’s as if once you pay to start the sampling process, the supplier NOW views that as the time to see if what’s quoted will work or not.

Supplier’s expect back-and-forth in the quoting process…fair enough. But far too often, they rely on the hashing out process to determine what’s needed instead of putting forth their own effort to determine a quote that’s as precise as possible.

Also, to be fair to the supplier, if they’re constantly asked to quote and spend energy on determining pricing…and the orders aren’t closing, it’s hard to expect them to put forth 100% effort when the buyers aren’t clear on possibility of order.

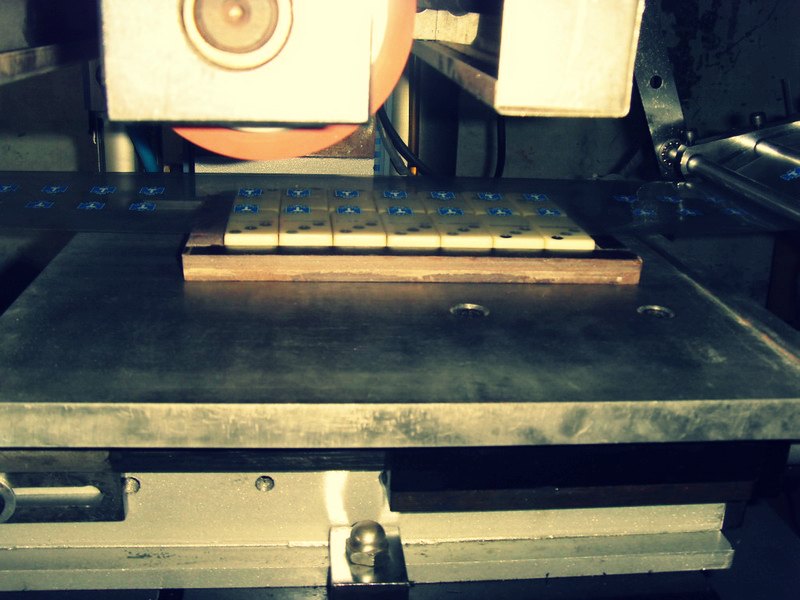

Sampling

The supplier put forth effort and quoted to the nines, but after the sampling process, things change. To reiterate, when developing something new, as an importer, be prepared for something to come to light.

When you’re developing a product and working in customization, let your customers know that this price is subject to change based on final sample. If your customers can’t handle this truth, then include sufficient padding in pricing to mitigate the change.

China Sourcing Basics

Let me share what I've learned about China Sourcing.

Provide your email & receive free ebook: 40 Tips for Emailing China Suppliers.

I'll never spam. I'll share tips on Private Labeling, Sourcing and China Business.

You have Successfully Subscribed!